Zollner Electronics GmbH

Success Story

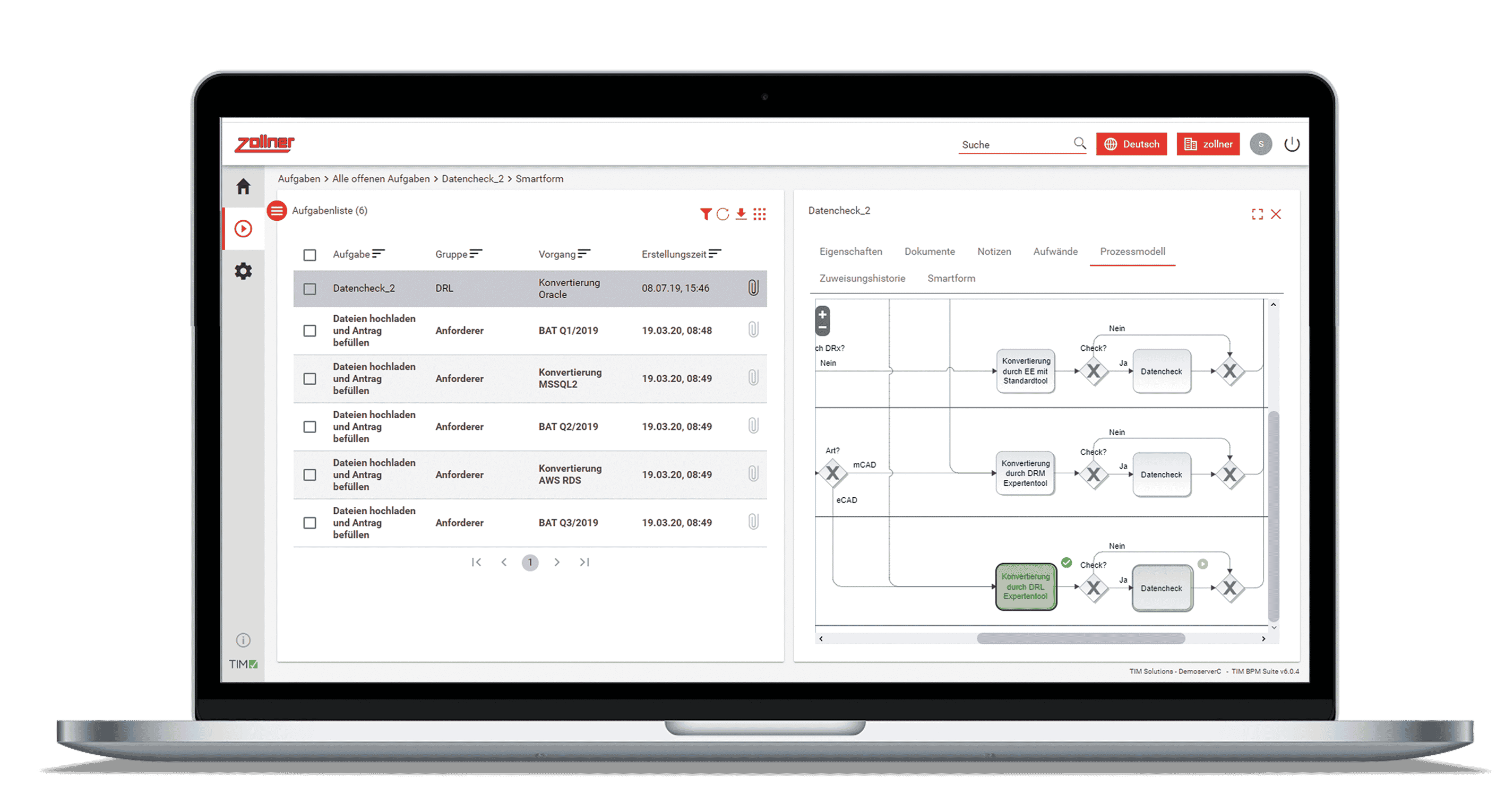

Standardization of the highly dynamic and complex change process

Complex mechatronic systems, from development to after-sales service: As a partner of globally operating top companies as well as small and medium-sized enterprises, Zollner Elektronik AG offers cross-industry system solutions. The family-owned company was founded in 1965 in Zandt, Bavaria. Through continuous organic growth, the group of companies has established itself as the market leader in Europe and among the top 15 EMS service providers worldwide with over 20 international locations.

“Mapping the change process in TIM resulted in considerable cost and quality benefits.”

Initial situation

Large number of documents (>200,000), data and deadlines for every single customer change request (and there are around 25,000 every year)

Lengthy throughput times when processing changes

Difficult change traceability

Time-consuming collection of process KPIs, such as throughput time and cost per change

Lack of transparency leading to an unstructured processing of changes

“TIM Solutions is a flexible partner that responds to requests and requirements and implements issues quickly.”

Requirements

All types of changes (from simple to highly complex) must be mappable using a process.

Despite having a standardized process, Zollner also needs a certain amount of flexibility (e.g., option for the specialist department to make last-minute process changes, illustration of standard-specific requirements).

Employees should only be informed of a change if that information is actually relevant to them.

The system and the process should be easy to handle for every employee.

The change owner should have a clear overview of the processing status of the changes in their division at all times.

It should be possible to compile the total time required to process an individual change.

It should be possible to identify process vulnerabilities and easily implement improvements at any time.

“With TIM, transparency and traceability across the entire process chain could be significantly increased.”

Successes

Global standardization of the process (with mapping of the standard-specific requirements)

Continuous improvement of the process/workflow (functional extensions such as RPA interface)

Clear improvement in data quality

Implementation in 6 different languages at Zollner (national and international)

Use of the intuitive TIM interface by 3,000 users, with an average of 900 users logging into TIM every day

Traceability across the entire process chain

More than 10 additional processes already implemented (e.g. PCN Management, NPI, Material Master, Deviation, Work Center Creation, Additive Manufacturing Request)

“We have introduced the TIM BPM Suite internationally in 6 different languages. The intuitive TIM interface is used by around 3,000 employees – and by an average of 900 on a daily basis!”